Description

Specialized Wagon Brake Solutions – Direct from Factory Floor

Targeting the Estate Market Opportunity

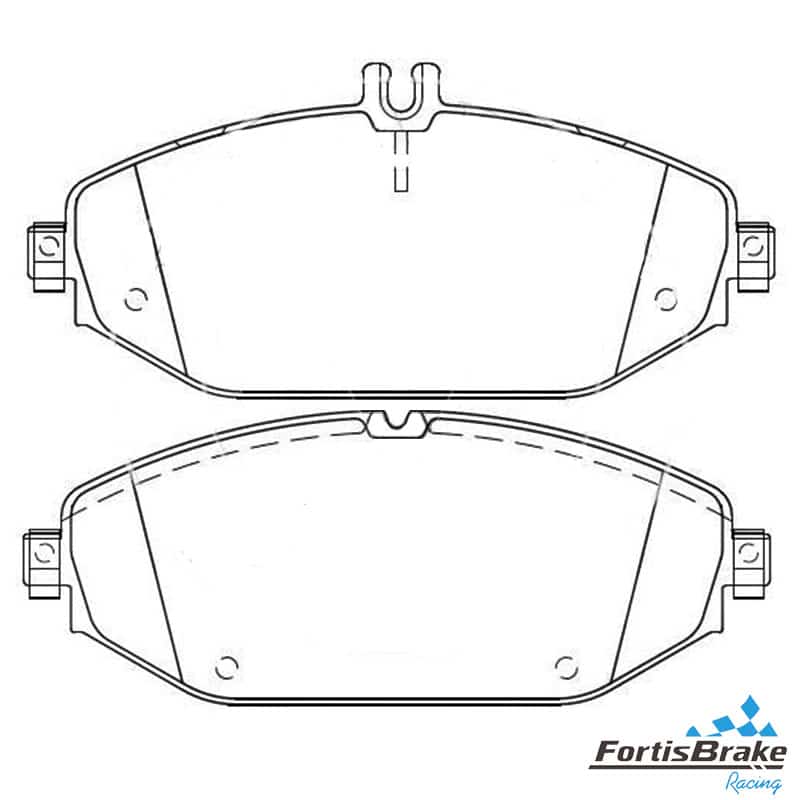

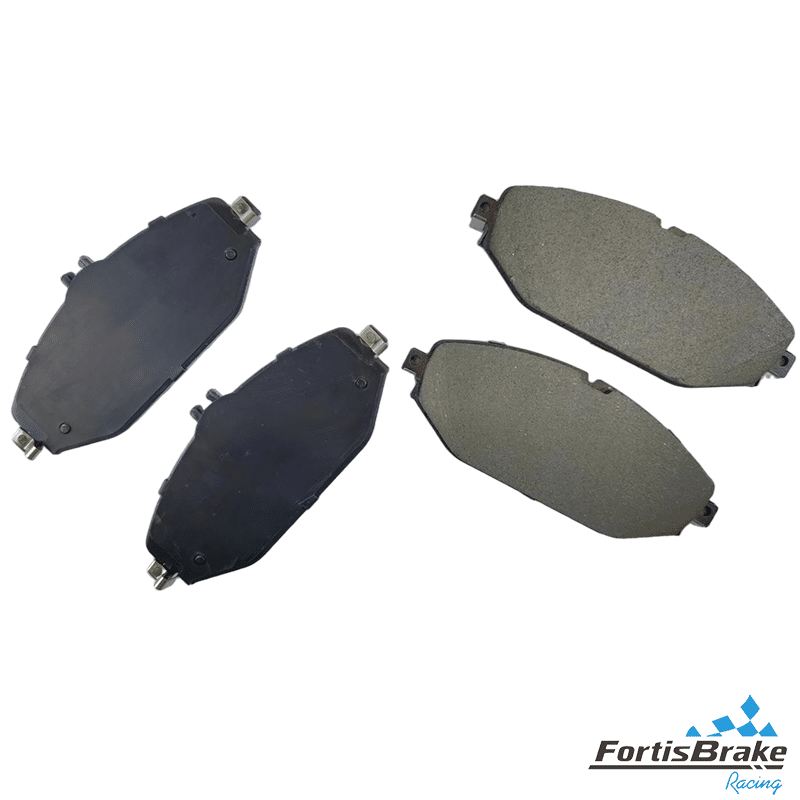

The Mercedes-Benz C-Class T-Model represents a unique market segment where performance meets practicality. Our D1794 Mercedes C-Class T-Model brake pads are specifically engineered for the increased braking demands of fully-loaded estate vehicles, delivering consistent performance for both daily commuting and weekend adventures.

🚗 Vehicle Application Scope

Mercedes-Benz C-Class T-Model (S205) | 2014-Present

✓ C 200 T-Model (S205.242/S205.252)

✓ C 220 d T-Model (S205.214)

✓ C 250 T-Model (S205.245/S205.246)

✓ C 300 T-Model (S205.248/S205.283)

✓ C 350e T-Model (S205.247) - Hybrid Applications📋 Cross-Compatible OE Part Numbers

Primary Mercedes-Benz OE Numbers: ◦ A0064206920 – Standard brake pad set (front) ◦ A0064206820 – Alternative front pad configuration ◦ A0004209403 – Rear brake pad applications

◦ A0064207020 – Performance package variants

Secondary OE References: ◦ A0054208920 – AMG Line specific applications ◦ A0064208420 – Sport package configurations ◦ 0084201420 – Alternative part numbering system

⚙️ Factory Production Methods

Lean Manufacturing Approach: Our production facility employs Toyota Production System principles, ensuring zero-waste manufacturing while maintaining the precision required for D1794 Mercedes C-Class T-Model brake pads. This approach reduces costs while maintaining premium quality standards.

Six Sigma Quality Control:

- Define: Estate vehicle braking requirements analysis

- Measure: Precise friction coefficient monitoring

- Analyze: Load capacity vs. braking performance correlation

- Improve: Continuous compound formulation optimization

- Control: Statistical process control implementation

📊 Estate Vehicle Performance Requirements

| Load Condition | Brake Performance | Temperature Range |

|---|---|---|

| Empty Vehicle (1,500kg) | Standard coefficient 0.42μ | 0°C to 300°C |

| Half Load (1,750kg) | Maintained 0.40μ | 50°C to 450°C |

| Full Load (2,000kg) | Sustained 0.38μ | 100°C to 600°C |

| Towing Capacity | Emergency 0.45μ | Peak 650°C |

🎯 Market Positioning Strategy

Target Distribution Channels:

Primary Focus Areas:

→ European estate vehicle specialists

→ Family vehicle service centers

→ Commercial fleet maintenance providers

→ Performance wagon enthusiast shopsCompetitive Advantage Matrix: The T-Model market requires specialized knowledge of load distribution and braking dynamics. Our D1794 Mercedes C-Class T-Model brake pads address these unique requirements through advanced friction compound engineering.

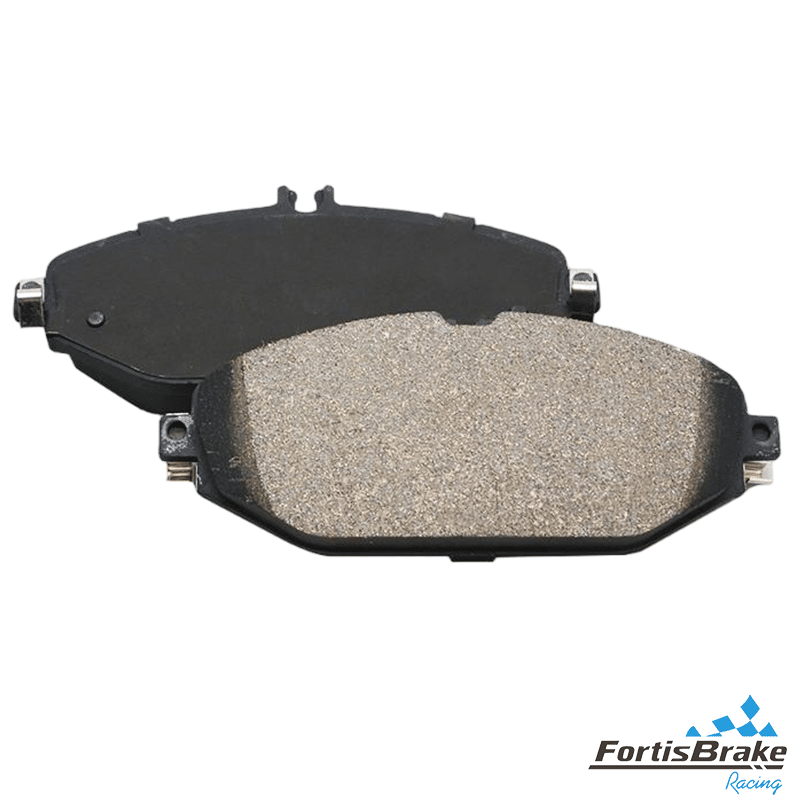

🔬 Advanced Material Science

Compound Formulation Strategy:

Base Matrix: Semi-metallic with ceramic reinforcement

Load Modifiers: Aramid fiber integration (15% by volume)

Heat Dissipation: Graphite particles (8% by weight)

Noise Control: Rubber granules (3% by weight)

Bonding Agent: Phenolic resin system rated 400°CEnvironmental Considerations:

- Copper-Free Formula: EU regulation compliance (ECE R90)

- Low-Dust Technology: Reduced wheel contamination

- Recyclable Materials: 85% post-use material recovery rate

💼 Distributor Business Model

Volume-Based Pricing Structure:

| Order Quantity | Unit Price | Margin Opportunity |

|---|---|---|

| 25-49 sets | Standard Rate | 35% markup potential |

| 50-99 sets | 8% discount | 42% markup potential |

| 100+ sets | 15% discount | 48% markup potential |

Inventory Velocity Analysis: T-Model vehicles typically require brake service every 35,000-40,000 miles due to increased vehicle weight and usage patterns, creating predictable replacement cycles for distributors.

📈 Quality Metrics & Validation

Factory Testing Protocols:

Dynamometer Validation:

- Simulated estate loading scenarios

- Temperature cycling with cargo weight simulation

- European driving pattern replication

- Noise level verification (<65dB)

Field Testing Program: Our D1794 Mercedes C-Class T-Model brake pads undergo real-world testing in partnership with European fleet operators, ensuring performance validation under actual service conditions.

📦 Professional Packaging Solutions

B2B Distribution Options:

Standard Professional Packaging: □ Individual boxes with technical data sheets □ QR codes linking to installation specifications

□ Multi-language documentation (English/German) □ Traceability codes for quality tracking

Bulk Distribution Cases: □ 20-set commercial cases with foam protection □ Integrated inventory management labels □ Custom branding opportunities (500+ set minimum) □ Just-in-time delivery scheduling available

🏭 Manufacturing Warranty Coverage

Factory-Direct Guarantee:

- 24-month manufacturing defect coverage

- Batch traceability for quality issues

- Technical specification support for distributors

- Replacement product expedited shipping program

Factory specializes in manufacturing – installation services provided by certified technicians only.

Ready to Capitalize on the Growing Estate Market?

The Mercedes C-Class T-Model segment continues expanding as families seek premium utility vehicles. Partner with our factory to secure your position in this profitable niche market with D1794 Mercedes C-Class T-Model brake pads that deliver the performance estate vehicle owners demand.

Contact our Export Division for volume pricing and distribution territories.