# Wholesale & OEM Service

Low Metallic Brake Pads Factory Direct

FortisBrake is a leading low metallic brake pads manufacturer and supplier from China, offering wholesale and OEM solutions worldwide. With advanced production technology and strict quality control, our low metallic brake pads deliver reliable braking performance, reduced noise, and long service life for modern vehicles. Choose FortisBrake for high-quality brake pad supply, bulk orders, and custom solutions tailored to your needs.

About Us

Our Low Metallic Brake Pads

Our brake pads combine organic materials with 10-30% metallic fibers for optimal performance.

Key Benefits:

- Superior heat management for consistent braking

- Quiet operation with minimal dust

- Long-lasting - 30,000 to 50,000 km lifespan

- Extends rotor life and reduces maintenance

- 100% asbestos-free and safe

- Excellent performance for heavy vehicles

- Ready to use - no break-in period required

Perfect for drivers who want reliable, quiet braking with reduced maintenance.

Brake Pad Expertise

Our production process is powered by advanced technology and rigorous quality checks, ensuring every brake pad delivers superior performance:

Precision Engineering

Designed with advanced technology to ensure maximum braking power and control

Ideal Uses for Low Metallic Brake Pads

FortisBrake low metallic brake pads are widely chosen for vehicles that demand stronger braking performance. They are especially suitable for heavier passenger cars, SUVs, trucks, and performance-focused models thanks to their excellent heat dissipation and powerful stopping capability

European Premium Cars

Trucks & SUVs

Asian and American Models

Low metallic frictions materials

FortisBrake low metallic brake pads are engineered from a precise blend of organic and metallic materials, optimizing friction, heat dissipation, and consistent braking performance under extreme conditions

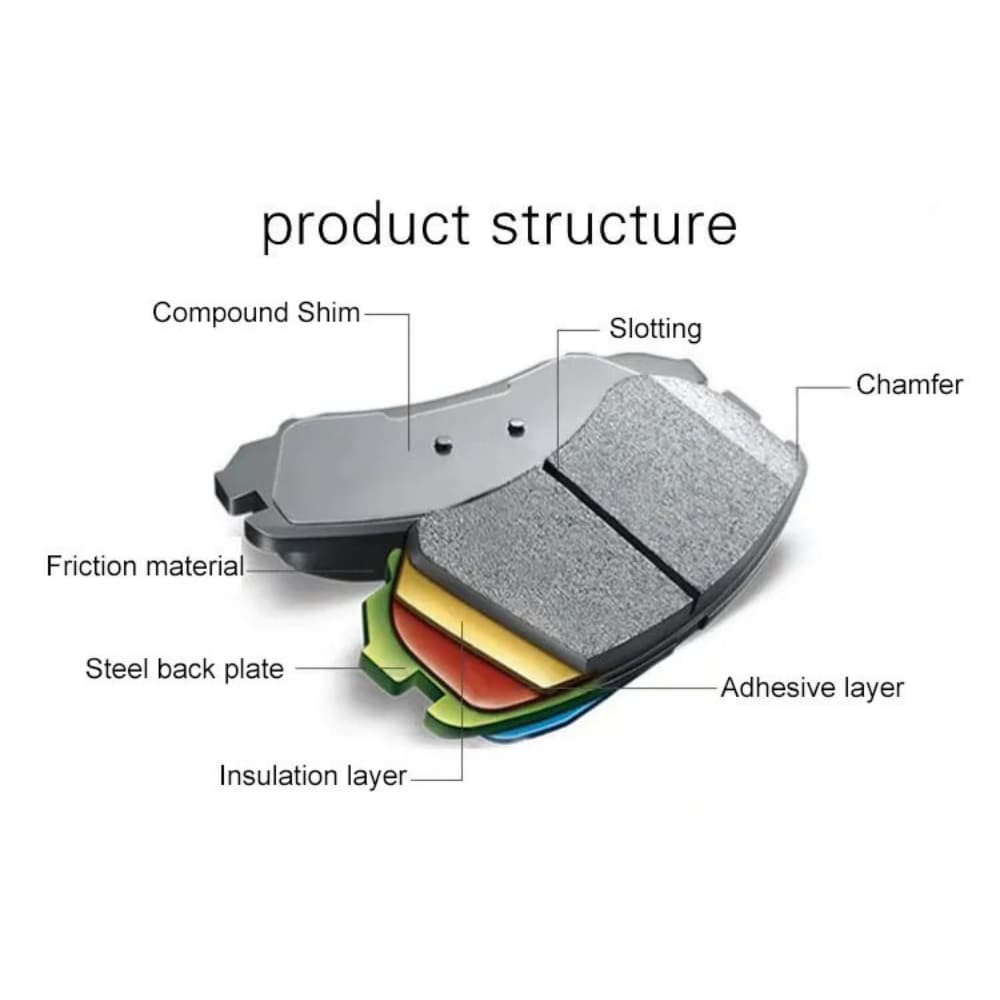

Key Components

FAQ

Q: What are Low Metallic Brake Pads and how do they differ from other brake pad types?

A: Low Metallic Brake Pads are high-performance brake pads manufactured using our advanced formula technology, containing typically less than 30% metallic content. Compared to traditional Semi-Metallic Brake Pads, our Low Metallic Brake Pads deliver significantly reduced noise, less dust generation, while maintaining superior braking performance and heat resistance. As a professional Brake Pad Manufacturer, we ensure every pad meets stringent OE standards and FMVSS 105/106 certification requirements.

Q: Which vehicle applications and markets do your Low Metallic Brake Pads cover?

A: Our Low Metallic Brake Pads cover over 5,000 part numbers, including:

- Passenger Vehicles (sedans, SUVs, crossovers)

- Light Commercial Vehicles (pickup trucks, vans)

- Performance Vehicles (sports cars, luxury vehicles)

Products are widely used in OEM supply and aftermarket sectors. We maintain a comprehensive Vehicle Application Database and offer Custom Brake Pad Development services. Our customization capabilities meet diverse market performance requirements and regional specifications.

Q: What are your wholesale pricing policies and minimum order quantities (MOQ)?

A: As a leading Brake Pad Supplier, our wholesale terms include:

- Standard Product MOQ: 50 sets per part number

- Custom Product MOQ: 1,000-2,000 sets (depending on complexity)

- Volume Discounts: Competitive pricing tiers based on order quantity

- Payment Terms: T/T, L/C, and flexible payment options

We offer competitive wholesale prices and flexible bulk order solutions, supporting private label OEM services. Long-term partners enjoy VIP pricing and priority supply guarantees.

Q: How do you ensure quality control and what certification standards do you meet?

A: Our Low Metallic Brake Pad production strictly follows international standards:

- ISO/TS 16949 Quality Management System

- FMVSS 105/106 Federal Motor Vehicle Safety Standards

- ECE R90 European Certification

- SAE J2430 Brake Lining Quality Standards

Every batch undergoes rigorous quality testing:

- Material Composition Analysis

- Friction Performance Testing

- Wear Rate & Durability Testing

- Noise, Vibration & Harshness (NVH) Testing

- Thermal Performance Evaluation

We provide Quality Assurance Certificates and product liability insurance, ensuring zero-defect quality delivery.

Q: What custom development services do you offer and what are the lead times?

A: As a specialized Custom Brake Pad Manufacturer, we provide comprehensive customization services:

Customization Options:

- Friction Formula Development (proprietary compound formulation)

- Performance Optimization (tailored for specific applications)

- Private Label Manufacturing (branded packaging solutions)

- Special Coatings & Treatments (anti-corrosion, noise dampening)

- Application-Specific Design (racing, heavy-duty, eco-friendly)

Development Timeline:

- Standard Modifications: 2-3 weeks

- New Formula Development: 4-6 weeks

- Complete Custom Solutions: 6-8 weeks

Our dedicated R&D team and state-of-the-art testing laboratory ensure custom products exceed your specific market requirements.

Q: What are your logistics and after-sales service policies?

A: Shipping & Logistics:

- Global Distribution Network: Serving major markets worldwide

- Fast Delivery: 7-15 days for standard products

- Flexible Packaging: Supporting various packaging requirements

- Multiple Incoterms: FOB, CIF, DDP options available

After-Sales Support:

- 24-Month Warranty Coverage

- 24/7 Technical Support Team

- Installation Guidelines & Training

- Performance Monitoring Programs

- Expedited Warranty Claims Processing

We are committed to our customer-first service philosophy, providing professional after-sales support to all wholesale partners and custom clients, building long-term strategic partnerships.

Contact us to get product catalogue