Description

D1050 Brake Pads High Performance – Premium Specialist

As a leading brake pad manufacturer, we specialize in producing premium D1050 brake pads high performance solutions designed for demanding sports car and luxury vehicle applications. Our manufacturing facility combines advanced production technology with rigorous quality control to deliver consistent, reliable braking performance serving performance vehicle enthusiasts and fleet operators worldwide.

Application: High-performance sports cars and luxury vehicles

Material: Premium ceramic brake pads and semi-metallic formulations available

Certification: ISO/TS 16949, ECE R90 compliant

Location: Front axle brake pads

Brake System: Brembo brake pads compatible

Technical Specifications

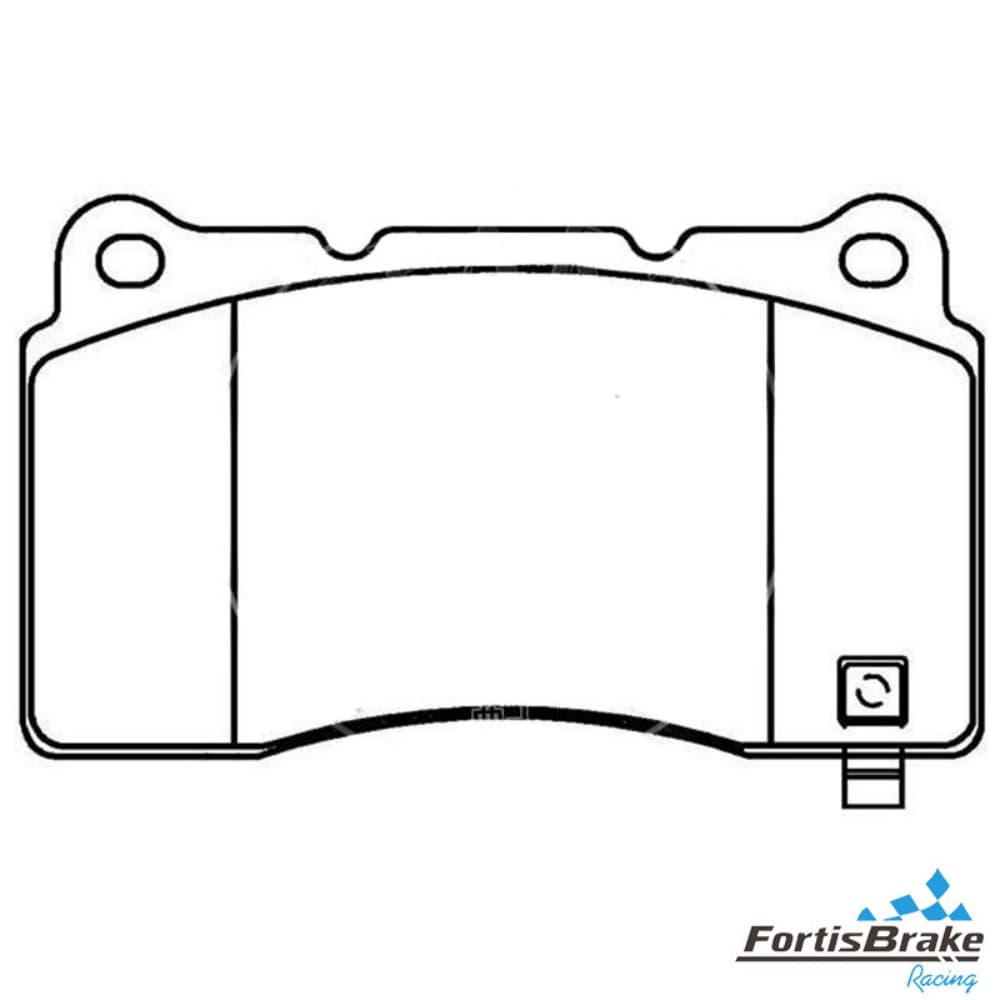

| Specification | Details |

|---|---|

| Width | 131.8 mm |

| Height | 77.3 mm |

| Thickness | 14.5 mm |

| FMSI Number | 7919-D1050 |

| Friction Material | Semi-metallic/Premium ceramic brake pads options |

| Temperature Range | -40°C to +450°C |

| Coefficient of Friction | 0.38-0.48 μ |

| Wear Rate | <0.20 mm/1000 cycles |

| Shear Strength | >2.8 MPa |

Compatible Vehicle Applications

Oullim

- Spirra (2008-2017) 2.7L

Honda

- Civic Type R (FK2) (Imported) (2015-present) 2.0T

- Civic Type R (FK8) (Imported) (2017-present) 2.0T

- Civic Type R (FL) (Imported) (2022-present) 2.0T (420T)

Buick

- Regal GS (E2SB) (2017-present) 2.0T (28T)

- Regal GS (SGM E10) (2009-2017) 2.0T

Dodge

- Viper GTS (ZD / VX) (Imported) (2013-2017) 8.4L

Ford

- Mustang Boss 302 (S197) (Imported) (2010-2014) 5.0L

- Mustang GT (S197) (Imported) (2011-2014) 5.0L

- Mustang GT500 (S197) (Imported) (2005-2014) 5.4T

- Mustang GT500 (S197) (Imported) (2005-2014) 5.8T

Cadillac

- ATS (Imported) (2013-present) 2.0T

- ATS-L (2013-2020) 2.0T

- CT6 (CK1) (2015-present) 2.0T (28T)

- CT6 (CK1) (2015-present) 2.0T (30E) – Plug-in Hybrid

- CT6 (CK1) (2015-present) 3.0T (40T)

- CTS (Third Generation) (Imported) (2013-present) 2.0T (28T)

- CTS-V (First Generation) (Imported) (2003-2006) 5.7L

- STS (Imported) (2005-2008) 3.6L

- STS (Imported) (2005-2008) 4.6L

- XTS (2012-present) 2.0T

- XTS (2012-present) 3.6L

QiuTian

- K50 (2015-present) Electric Vehicle

Chevrolet

- Camaro (Imported) (2014-present) 6.2L

- Camaro RS (Imported) (2016-present) 2.0T

- Corvette (C7) (Imported) (2014-present) 6.2L

Mitsubishi

- Lancer Evo (9th Generation) (Imported) (2000-2007) 2.0T

- Lancer Evo (10th Generation) (Imported) (2007-2016) 2.0T

Subaru

- Impreza WRX STi Hatchback (GR) (2006-2010) 2.5T

- Impreza WRX STi Sedan (GD) (2001-2007) 2.0T

- Impreza WRX STi Sedan (GV) (2003-2014) 2.5T

- Impreza WRX STi Sedan (VA) (2014-present) 2.5T

Tesla

- Model S Series: 60, 60D, 70, 70D, 75, 75D, 85, 85D, 90, 90D, 100D, P90D (2013-present)

- Model X Series: 60D, 75D, 90D, 100D, P90D, P100D (2015-present)

Hyundai

- Genesis Coupe (BK) (Imported) (2008-present) 2.0T

- Genesis Coupe (BK) (Imported) (2008-present) 3.8L

XPeng

- P7 (2019-present) Electric Vehicle

OE Reference Numbers

| OE Number | Formatted Number |

|---|---|

| 58101-2MA10 | 581012MA10 |

Premium Raw Materials

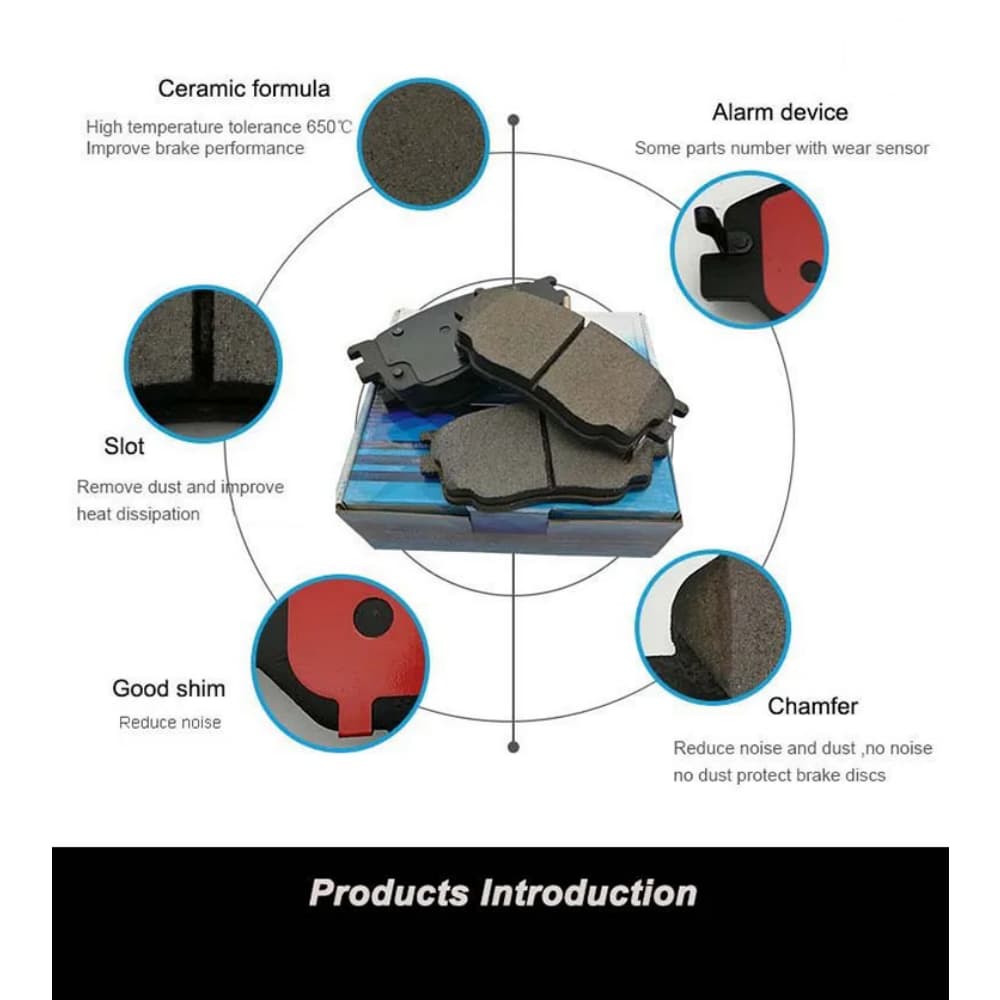

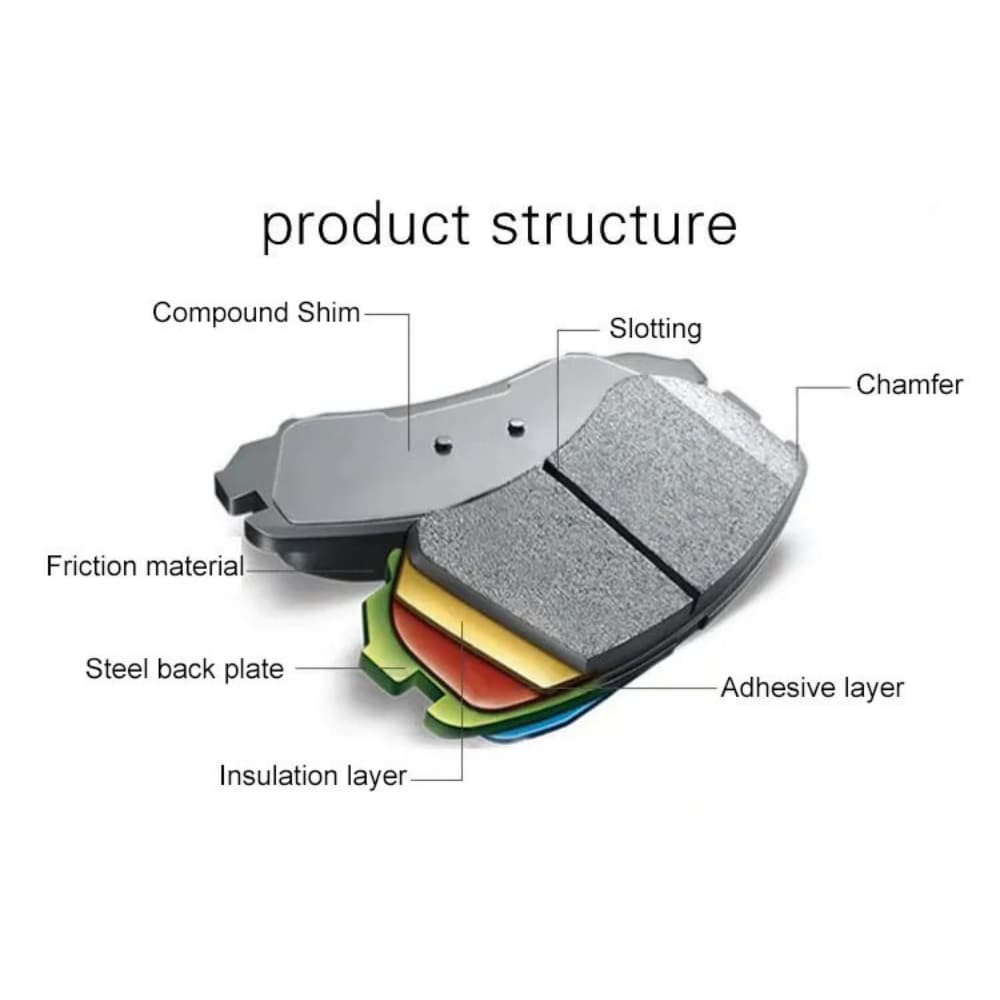

High-Performance ceramic brake pads Formulations: Advanced ceramic compounds engineered for extreme heat dissipation and consistent performance under high-stress braking conditions.

Asbestos-Free Construction: 100% asbestos-free materials ensuring environmental safety and regulatory compliance.

Premium Semi-Metallic Options: Precisely balanced metallic content optimized for front axle brake pads applications.

Strict Material Control: Rigorous raw material selection and quality verification processes ensure batch-to-batch consistency.

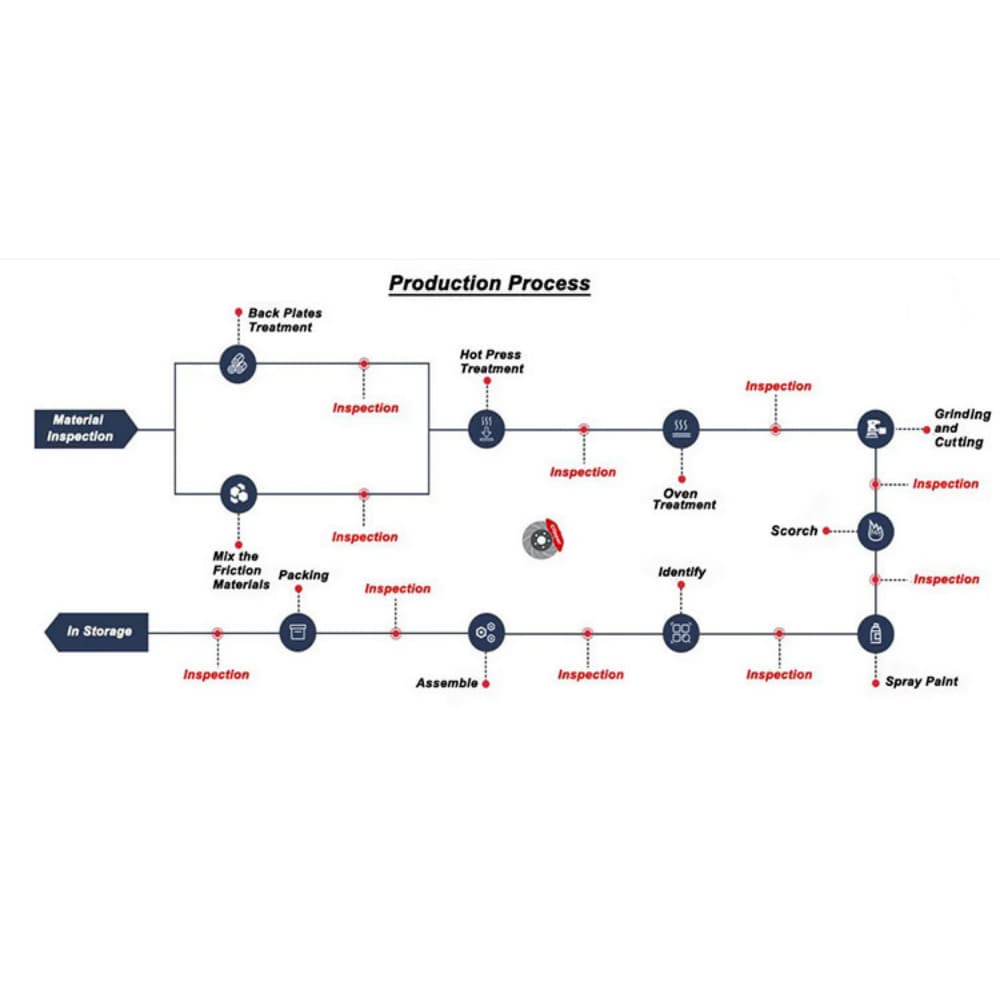

Quality Assurance

- Advanced friction material formulation specifically designed for performance vehicles

- Computerized testing protocols including fade resistance and thermal cycling

- Batch-to-batch consistency monitoring with statistical process control

- Performance validation testing on actual vehicle platforms

- Premium material sourcing ensures consistent top-quality products

Production Capabilities

- High-volume manufacturing capacity with flexible production scheduling

- Multi-layer protective packaging system designed for international shipping

- Custom labeling and branding available for qualified partners

- Just-in-time delivery scheduling to optimize inventory management

Secure Packaging & Shipping

Multi-Layer Protection: Professional pallet wrapping with stretch film and reinforced corrugated cartons

Damage Prevention: Specialized packaging ensures products arrive in perfect condition

Export-Grade Packaging: Designed specifically for international shipping and handling

Quality Guarantee: Products delivered intact with comprehensive packaging protection

Technical Support

- Application engineering assistance for complex fitment requirements

- Comprehensive cross-reference verification services

- Detailed installation guidance documentation

- Technical troubleshooting support with experienced specialists

Key Product Benefits

Superior Performance: Engineered specifically for demanding vehicle applications with enhanced stopping power, consistent fade resistance, and optimal pedal feel.

Extended Service Life: Premium friction materials and reinforced backing plates ensure longer wear life and reduced maintenance costs even under aggressive driving conditions.

Global Compliance: Manufactured to international safety standards including ECE R90 certification with comprehensive testing documentation.

Competitive Pricing: Direct manufacturer pricing with volume discounts available for qualified distributors and performance shops.

Global Distribution

We serve automotive parts distributors, performance vehicle specialists, racing teams, and luxury car service centers worldwide. Our experienced export team provides comprehensive support from initial inquiry through ongoing partnership development.

Minimum Order Quantities: Flexible MOQs to support businesses of all sizes

Lead Times: Standard 15-30 day production scheduling with expedited options available

Payment Terms: Competitive terms for established partners with credit facilities

Shipping: Worldwide logistics support with preferred carrier rates and tracking

Ready to discuss your brake pad requirements? Our technical sales specialists are available to provide detailed quotations, application support, and partnership opportunities for premium braking solutions.

Global Reach | Local Support | Manufacturing Excellence

Delivering reliable, high-performance braking solutions for automotive professionals worldwide.