Description

Manufacturing Overview

Our state-of-the-art production facility manufactures these 2016 Ford Explorer brake pads using precision-controlled processes that ensure consistent quality across all production runs. Each set of 2016 Ford Explorer front rear brake pads undergoes multiple quality checkpoints before packaging, guaranteeing reliability for demanding commercial applications.

The D1611 series represents our commitment to delivering superior brake components that meet the stringent requirements of professional automotive service providers. Our manufacturing approach combines traditional craftsmanship with cutting-edge technology to produce brake pads that exceed industry expectations.

Cross Reference Compatibility Matrix

Our comprehensive cross-reference system ensures seamless integration with existing parts management systems. These 2016 Ford Explorer brake pads maintain compatibility across multiple manufacturer specifications:

| BENDIX | FMSI | FMSI | FORD |

|---|---|---|---|

| D1611 | D1611-8855 | D1611-8881 | DG1Z-2001-A |

| FORD | FORD | FORD | FORD |

| DG1Z-2001-B | DG1Z-2001-C | DG1Z-2001-D | DG1Z-2001-E |

| FORD | FORD | FORD | FORD |

| DG1Z-2001-F | FU2Z-2V001-D | G2MZ-2V001-AU | GB5Z-2001-A |

| FORD | FORD | HI-Q | KASHIYAMA |

| GB5Z-2001-B | GU2Z-2V001-C | SP1620 | D20079H |

Advanced Material Science

Our 2016 Ford Explorer front rear brake pads incorporate proprietary friction material compounds that deliver consistent performance across varying temperature ranges and operating conditions. The D1611 formulation provides optimal balance between stopping power and component longevity.

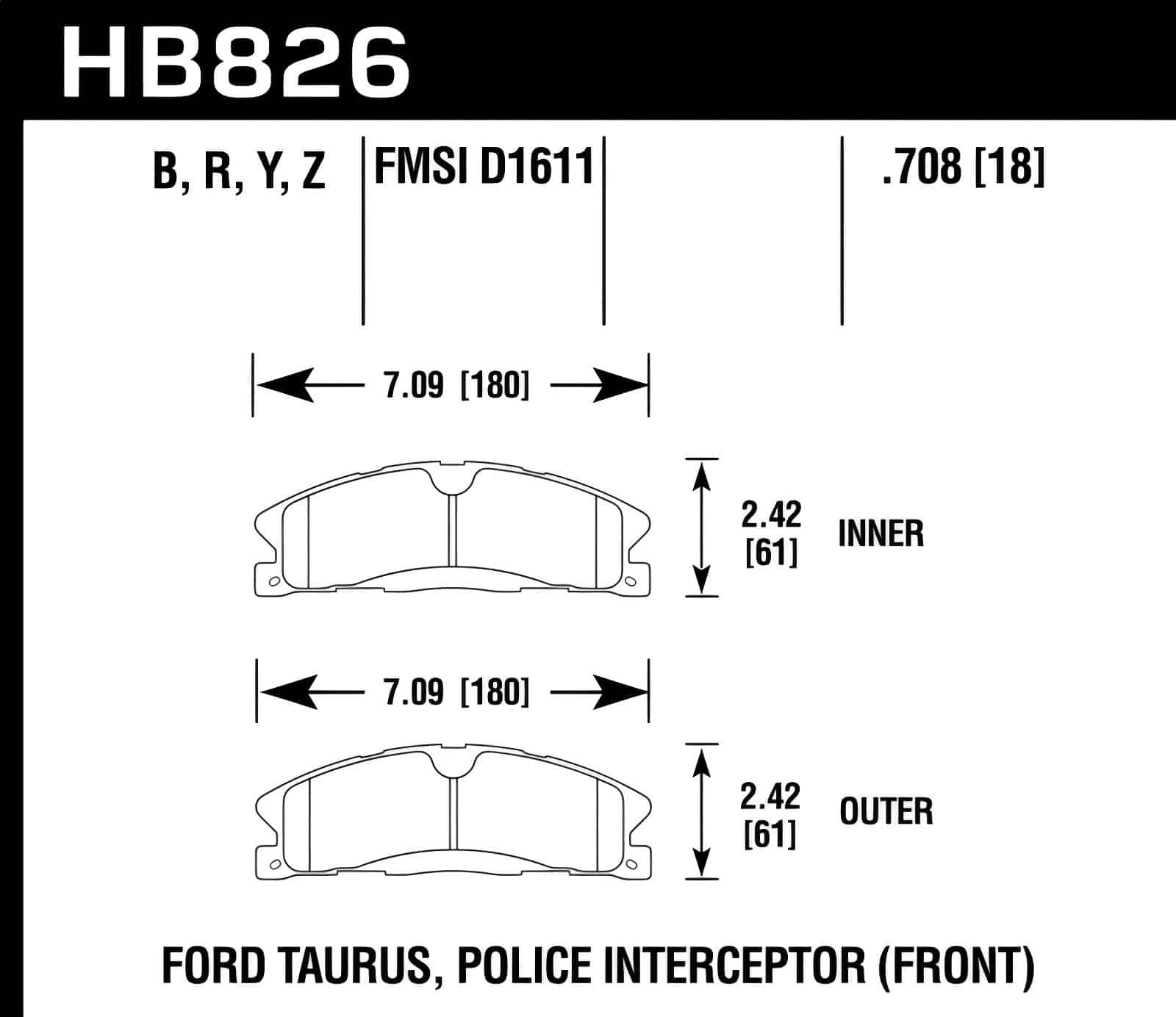

Technical Specifications

| Primary Part Number | D1611 (BENDIX Standard) |

|---|---|

| Ford OEM Reference | DG1Z-2001-D (Primary Application) |

| Friction Material Type | Semi-Metallic High Performance |

| Operating Temperature Range | -40°F to 950°F (-40°C to 510°C) |

| Friction Coefficient | 0.35-0.45 μ (Variable Load) |

| Service Life Expectancy | 40,000-60,000 Miles (Typical Use) |

Industrial Quality Features

- Precision Manufacturing: CNC-machined backing plates ensure perfect fitment and optimal heat transfer characteristics.

- Advanced Bonding Technology: Proprietary adhesive systems eliminate pad separation under extreme conditions.

- Noise Reduction Engineering: Multi-layer shim construction minimizes brake noise and vibration.

- Thermal Management: Engineered chamfers and slots optimize heat dissipation patterns.

- Extended Durability: Enhanced wear indicators provide accurate service life monitoring.

Production Quality Control

Every batch of our 2016 Ford Explorer brake pads undergoes comprehensive testing protocols including coefficient of friction analysis, thermal cycling evaluation, and durability assessment. Our ISO 9001:2015 certified facility maintains strict quality standards throughout the manufacturing process.

Statistical process control methods ensure consistent product characteristics across all production runs, providing reliable performance for professional automotive applications requiring 2016 Ford Explorer front rear brake pads.

Industrial Sales & Technical Support

For detailed specifications, volume pricing, and technical consultation regarding our 2016 Ford Explorer brake pads D1611 and DG1Z-2001-D compatible products, contact our industrial sales division. We provide comprehensive support for B2B customers requiring reliable brake component solutions.